Mastering In-Mold Decorations: Strategies, Patterns, and Best Practices for Ideal Outcomes

In the realm of production, the art of in-mold decorations stands as an essential aspect of product style and production. In-Mold Decorations. By delving into the methods, patterns, and finest practices that underpin successful in-mold design procedures, services can unlock a realm of possibilities that not only boost the aesthetic appeal of their items yet likewise improve production effectiveness and strengthen consumer involvement.

Product Choice

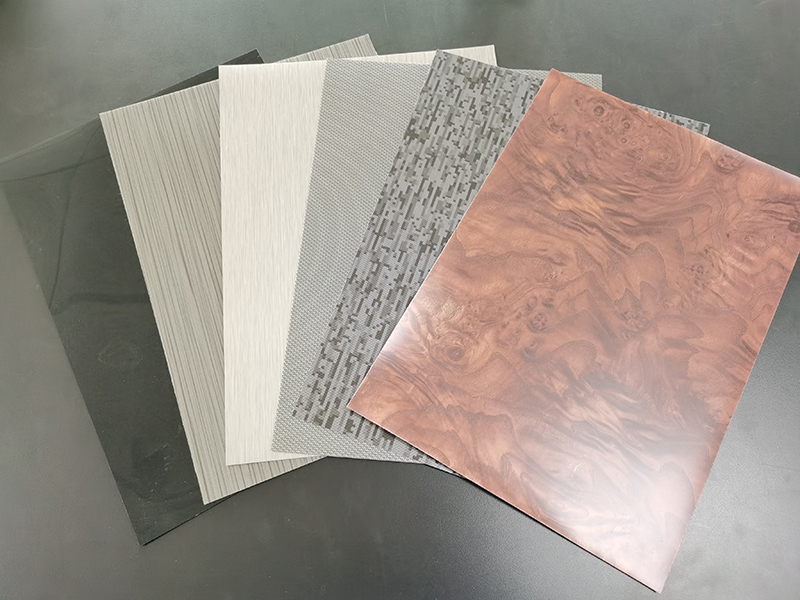

Material selection is an essential aspect of understanding in-mold decors, as it straight impacts the high quality and sturdiness of the final item. When picking products for in-mold decorations, it is essential to take into consideration factors such as compatibility with the molding process, the wanted visual outcome, and the environmental problems the product will certainly face.

Additionally, the chosen product should possess good bond homes to ensure that the decor adheres securely to the substrate during the molding process. Bond between the design and the product is essential for stopping delamination and making certain resilient visual allure. Additionally, materials with high heat resistance are liked for in-mold designs, particularly for items that will certainly be subjected to raised temperature levels during their lifecycle. By thoroughly choosing the suitable product for in-mold decors, producers can boost the total quality and longevity of their products, meeting the expectations of both customers and end-users.

Layout Advancement

A vital consider progressing the area of in-mold designs is the continual expedition and execution of style development strategies. Design innovation plays an essential duty in enhancing the visual allure, performance, and general top quality of items produced making use of in-mold decor procedures. By integrating cutting-edge style aspects, makers can differentiate their products on the market, draw in customers, and remain ahead of rivals.

Among the crucial aspects of style advancement in in-mold decorations is the integration of elaborate patterns, appearances, and graphics that were formerly testing to accomplish with standard design approaches. Advanced technologies such as 3D printing and digital design tools make it possible for developers to develop facility and in-depth styles that can be flawlessly moved onto shaped parts. Additionally, the usage of vibrant shades, metal surfaces, and special results like gloss or matte structures can additionally raise the visual charm of in-mold enhanced products.

Furthermore, design advancement extends past aesthetics to encompass functional improvements such as ergonomic forms, integrated features, and customizable aspects that satisfy details user demands. By accepting layout technology, suppliers can unlock new opportunities for personalization, creativity, and product differentiation in the affordable landscape of in-mold designs.

Manufacturing Performance

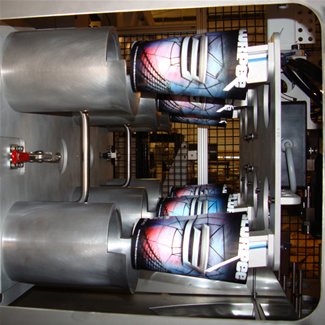

Effective manufacturing procedures are vital for equating the cutting-edge designs established in the area of in-mold decors into top quality completed products that satisfy market demands and consumer expectations. In the world of in-mold designs, manufacturing effectiveness includes numerous crucial facets that contribute to the total success of the production process. One crucial aspect is the optimization of mold style and tooling to guarantee exact and smooth decor transfer onto the end product. By fine-tuning mold setups and purchasing top notch tooling materials, producers can enhance efficiency and consistency in manufacturing.

Furthermore, implementing automation and robotics in the production line can substantially improve performance by enhancing repetitive tasks and reducing the margin of error. Automation not just increases the production procedure yet likewise improves accuracy and repeatability, resulting in a much more top quality and consistent end product. Moreover, embracing lean production concepts, such as just-in-time supply monitoring and waste reduction techniques, can better improve manufacturing efficiency by reducing downtime and maximizing resource usage. Generally, an all natural strategy to manufacturing performance is vital in maximizing the potential of in-mold decoration techniques and accomplishing optimum cause the open market landscape.

Quality Assurance Steps

What are the key approaches for making sure strict quality assurance measures in the world of in-mold designs? Quality control measures are critical in in-mold design procedures to ensure the production of top quality and flawless ended up products. One essential technique is the implementation of strenuous assessment protocols at every phase of the manufacturing procedure. This involves conducting extensive visual evaluations, dimensional checks, and color uniformity official website assessments to identify any kind of inconsistencies or issues early on.

Using sophisticated innovations such as computerized inspection systems can additionally improve the quality control process by giving reputable and accurate information for analysis. These systems can discover blemishes that might be missed by hands-on examinations, thereby improving total product top quality and uniformity.

Normal training and development programs for workers associated with the in-mold decor procedure can additionally add to preserving top notch standards. By informing team on best practices, quality assumptions, and the value of focus to information, companies can cultivate a culture of high quality awareness throughout the company.

Customer Charm

To improve the marketability of in-mold decor items, catering and recognizing to consumer choices play a crucial duty in identifying their charm and success. Offering modification alternatives such as tailored designs, color variants, and textural aspects can significantly boost the appeal of in-mold decoration items.

Final Thought

In-mold decorations use a efficient and flexible means to improve item visual appeals. Understanding in-mold decorations needs an all natural method that thinks about all elements of the production procedure to make certain success.

In the world of manufacturing, the art of in-mold decors stands as a crucial facet of item style and production. Design technology plays a crucial function in boosting the aesthetic allure, capability, and total quality of products manufactured using in-mold decoration procedures.One of the crucial elements of layout technology in in-mold decors is the combination of detailed patterns, textures, and graphics that were previously challenging to attain with conventional decoration methods.Effective manufacturing procedures are essential for converting the ingenious styles established in the area of in-mold designs into premium completed items that satisfy market demands and customer expectations. Offering modification options such websites as individualized designs, color variations, and textural aspects can significantly enhance the allure of in-mold design products.